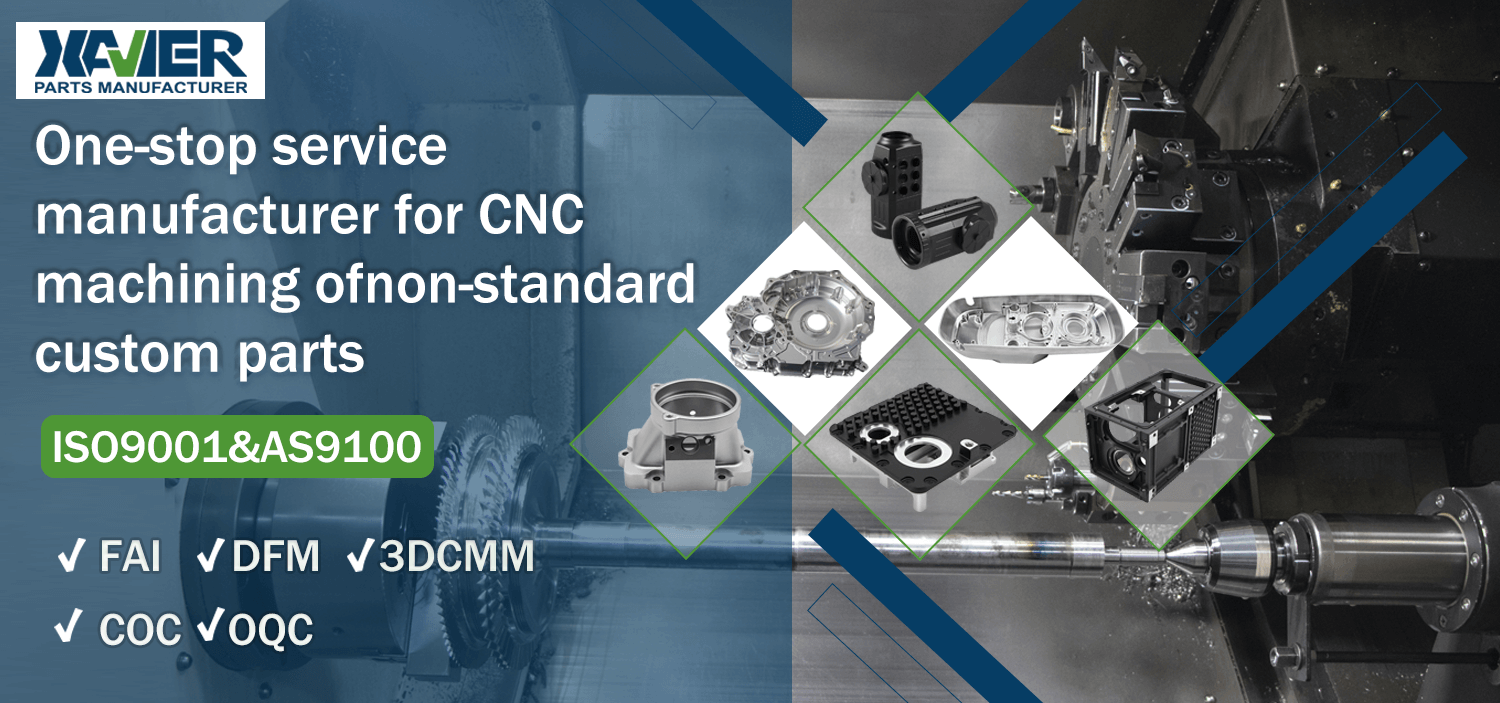

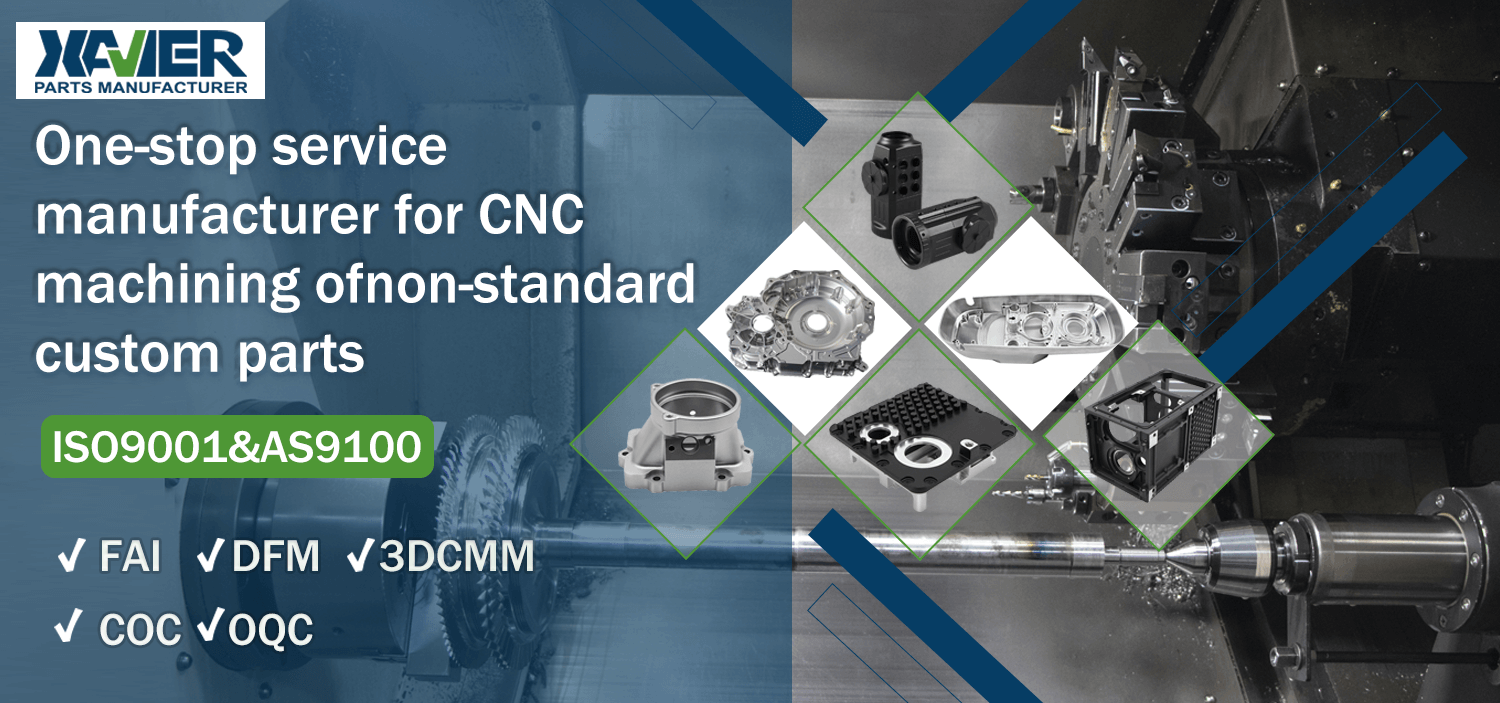

Professional parts machining factory

Dear customer, welcome to our website. On May 1, 2024, we have moved the website to https://www.xavier-parts.com. If you need to obtain support or quotation, please visit our New website.

Dear customer, welcome to our website. On May 1, 2024, we have moved the website to https://www.xavier-parts.com. If you need to obtain support or quotation, please visit our New website.